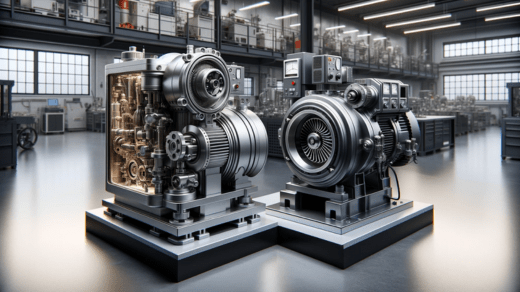

In the realm of industrial machinery, vacuum pumps play an indispensable role in a myriad of applications, from manufacturing processes to research laboratories. One of the standout performers in this category is the side channel vacuum pump, a remarkable innovation that has transformed the way we approach vacuum technology. In this comprehensive article, we delve deep into the world of dry vacuum pumps, exploring their mechanisms, applications, advantages, and why they have become a game-changer in the industry.

Understanding Dry Rotary Vane Vacuum Pumps

What Are Dry Rotary Vane Vacuum Pumps?

Dry rotary vane vacuum pumps are a type of positive displacement pump known for their reliability and efficiency. Unlike their oil-sealed counterparts, dry vacuum pumps operate without any lubrication fluid within the compression chamber, hence the name “dry.” Instead, they employ self-lubricating materials and innovative engineering to create a powerful vacuum.

The Mechanism Behind Dry Vacuum Pumps

The core of a dry rotary vane vacuum pump’s operation lies in its vane assembly. Inside the pump housing, a set of vanes, typically made of a robust material like carbon or PTFE, are positioned eccentrically. As the pump rotor rotates, these vanes slide in and out of their slots, creating chambers of varying volumes. This cyclical movement generates suction, drawing gas into the pump, and then compressing it as the chambers decrease in size.

Applications of Dry Vacuum Pumps

Dry rotary vane vacuum pumps have found their place in a multitude of industries due to their exceptional performance and versatility. Here are some key applications where these pumps shine:

1. Manufacturing

In manufacturing processes, dry vacuum pumps are invaluable for degassing resin, forming composite materials, and pick-and-place applications in electronics assembly. Their oil-free operation ensures that products remain uncontaminated and pristine.

2. Pharmaceuticals and Medical Devices

The pharmaceutical and medical device industries demand high levels of purity and reliability. Dry vacuum pumps are ideal for processes such as freeze-drying, solvent recovery, and packaging where maintaining a sterile environment is paramount.

3. Research and Development

Research laboratories rely on dry rotary vane vacuum pumps for a wide range of tasks, including vacuum filtration, glove box operations, and material testing. Their consistent vacuum levels and oil-free operation make them a preferred choice.

4. Food Processing

In the food industry, dry vacuum pumps are used for packaging, evaporation, and freeze-drying applications. Their ability to maintain product integrity by avoiding oil contamination is crucial in this sector.

Advantages of Dry Rotary Vane Vacuum Pumps

When it comes to choosing a vacuum pump, the advantages of dry rotary vane vacuum pumps become apparent:

1. Oil-Free Operation

Unlike oil-sealed pumps that require regular maintenance and oil changes, oil Vacuum Pumps operate without any lubrication fluid. This eliminates the risk of oil contamination in sensitive processes and reduces maintenance costs significantly.

2. Energy Efficiency

Dry rotary vane vacuum pumps are known for their energy efficiency. Their innovative design minimizes energy consumption, making them environmentally friendly and cost-effective.

3. High Reliability

The self-lubricating materials and robust construction of dry vacuum pumps result in exceptional durability and reliability. They can operate continuously for extended periods with minimal wear and tear.

4. Minimal Noise and Vibration

Compared to other vacuum pump types, dry rotary vane vacuum pumps produce less noise and vibration, creating a quieter and more comfortable working environment.

In the ever-evolving landscape of industrial technology, dry rotary vane vacuum pumps have emerged as a true game-changer. Their oil-free operation, energy efficiency, and wide range of applications make them a top choice for industries where precision, reliability, and product integrity are paramount. Whether you’re in manufacturing, pharmaceuticals, research, or food processing, dry vacuum pumps offer a reliable and efficient solution to your vacuum needs.